The innovation in engineering design and manufacturing continues to evolve around the globe as an everyday common-place occurrence in high tech sectors, having a strong multiplier effect on the regions economy. Concerning composite materials, upon success of unidirectional prepregs, multi-directional textile fiber composites are now changing the way advanced products are designed faster, stronger, and at lower cost. There are two main challenges that are deemed to be most relevant to current composite designers towards efficient and reproducible manufacture of textile composites:

- Mitigation of major defects such as ‘wrinkling’ and therefore reduction of production costs by correct selection of fabric materials and their lay-ups, optimum set-up of manufacturing steps, and waste management, e.g. by using near-net shape production methods;

- Implementation of high fidelity simulation tools, specially for forming parts with complex 3D shapes.

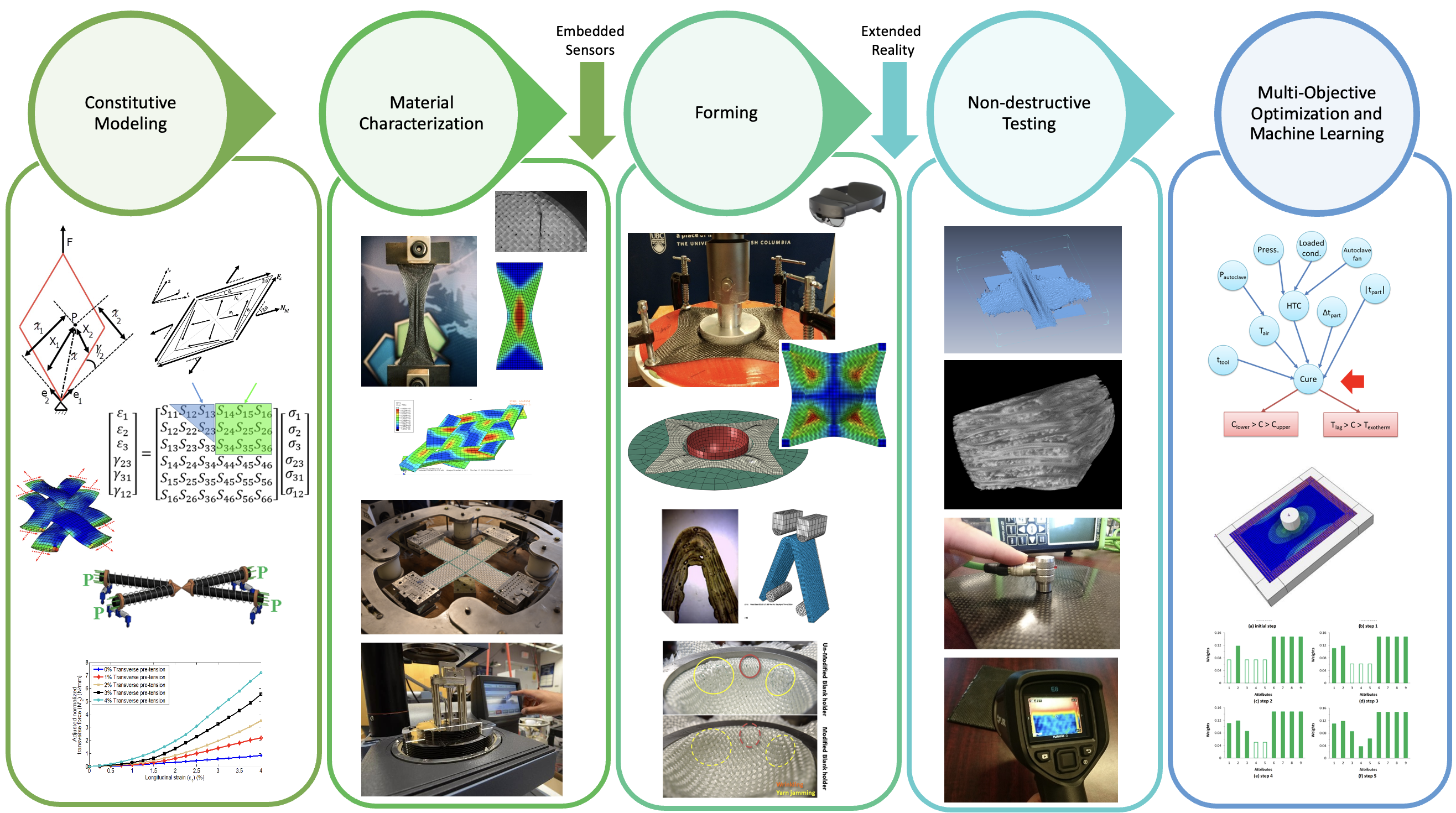

Recognizing these needs, researchers in our laboratory take a systemic building block approach (Image 1) to arrive at new design and manufacturing methods for advanced textile composites, starting from constitutive modeling of a given material constituents and their thermo-mechanical characterization using customized fixtures, to forming trials and multiscale simulations, non-destructive testing of the cured parts, and finally the multi-objective ‘robust’ optimization of the product development process at full-scale by means of statistical analysis tools and machine learning techniques.

To learn more about our activities in this area please read the Featured Article on Advanced Textile Source website.