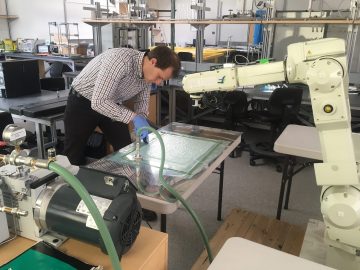

Towards Intelligent Fabric Forming Processes (Composites 4.0)

Industry 4.0 is now increasingly being heralded by the world’s leading industrialized countries as the fourth industrial revolution. The concept relies on integrating the recent advances of three core areas: cybernetics, the industrial internet of things (IIOT), and cloud computing and utilization of digitalized infrastructure to serve product design and manufacturing at large. In practice this is accomplished by creating a digital copy of modular cyber-physical (CP) factories, and subsequently using on-line sensing and data communication techniques along with networks of artificial intelligence (AIs) to enable optimal, sustainable and feasible decision-making in real-time and in a decentralized manner on the manufacturing floor. The CRN Okanagan laboratory in close collaboration with the Advanced Control & Intelligent Systems (ACIS) Laboratory specializes in implementation of Industry 4.0 concepts in composites manufacturing. For more information, please visit: I4.ubc.ca

UBCO team in Schneider Go Green Competition 2022

UBCO team, Iman Jalilvand, Niloofar Akbarian, Rohith JK, and Debangsha Sarkar, passed Schneider Go Green North America semi-finalist under supervision of Dr. Abbas Milani and Dr. Apurva Narayan and is selected among those advancing to the next round in the challenge to compete in the Regional Finals.

The proposed project aims to provide the AR-based solution to optimize the workflow in the inventory management systems by minimizing total costs and time resulting in smarter warehouse management in the supply chain. The proposed solution will provide additional insight for operators in warehouse centers by illustrating a small-scale digital twin of the inventory management system.

Schneider Go Green semi-final team presentation recording

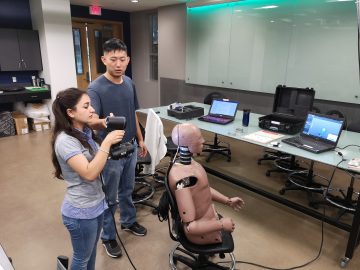

Beyond Industry…Health 4.0

Development of 3D printed yarn-based smart wearable sensors for real-time fitness monitoring and optimization

UBCO team in OpenCV AI Competition 2021

Development of a depth perception framework for detecting wrinkles and identifying their severity in textile composite materials

Capstone project highlight:

Development and Optimization of an Industry 4.0 Framework for Composites Manufacturing

Industry 4.0 is a modern paradigm in manufacturing processes whose principles include inter-connectivity, information transparency and decentralized decisions. In practice this amounts to using internet-connected technology to make data-driven decisions for the manufacturing process. With regards to composite manufacturing, the technological framework to accomplish this would include digitally-connected sensors, a centralized database, machine learning, and micro controllers. For the specific process of composite curing, the sensors would detect temperature and relay this information back to the processing unit, which could then control the curing oven accordingly. By establishing a solution under Industry 4.0 principles, a transferable workflow can be established forming a basis for future research.

The objective of this capstone project was to apply the principles of Industry 4.0 to optimize the composite manufacturing process of composite curing. This report details the problem formulation, design process, the end product and an evaluation of the overall success of the project.

Live prediction of soak time determination in a typical heat chamber

Online part quality monitoring for detection of wrinkles and fiber-path defects

Structural Health Monitoring in Sensor-Integrated Smart Composites

- Presents a comprehensive focus on sensor systems embedded in composite materials which provide the “monitoring” feature of this engineering design.

- Summarizes the fundamentals of structural health monitoring systems including the principles, characterization, and challenges presented by fabrication and signal processing methods.

- Includes two expanded case studies with analyses of challenges, testing methods, and solutions.

- Provides a detailed description of the testing methods used in these examples to understand how the novel sensors work in monitoring the condition of composite woven fabrics.